With the right automatic vape cartridge-filling machine, you can enhance filling accuracy, reduce labor costs, and deliver top-notch product quality. However, with so many options on the market—each with unique features—finding the perfect fit for your needs can feel overwhelming. In this article, we walk you through the essential features to look for in vape cartridge-filling machines and help you understand which machine specifications will best suit your operations.

How Do Vape Cartridge Filling Machines Enhance Production and Quality?

A vape cartridge filling machine is a specialized device designed to accurately and efficiently fill vape cartridges with oils, distillates, or other vaping liquids. These machines automate the filling process, making it faster, more precise, and less labor-intensive compared to manual filling methods.

Automated filling machines play a crucial role in enhancing product quality in several ways:

- Exact Product Volume: By ensuring each cartridge is filled with the precise amount of material, businesses can avoid issues with under or over-filled cartridges.

- Uniform Heat Distribution: Heat plays a significant role in the quality and appearance of vaporizer cartridges. Automated machines ensure the material is heated evenly, resulting in visually consistent and high-quality cartridges.

- Clean Filling Process: Many machines offer a cleaner filling process, preventing contamination. High-quality machines are designed to maintain cleanliness, a crucial aspect of producing high-quality vape cartridges.

Discover the Benefits Firsthand – Request a Demo Today!

Automatic vs. Manual Vape Cartridge Filling Machines

Automatic and manual vape cartridge filling machines each offer distinct advantages depending on production needs. Automatic filling machines are designed for high-volume production, filling hundreds or thousands of cartridges per hour with minimal oversight. They ensure consistency in fill levels, reduce waste, and improve efficiency, making them ideal for large-scale operations.

On the other hand, manual filling machines are more affordable, portable, and suitable for small-batch production or businesses just starting out. While they require more hands-on labor, they offer control over each cartridge, allowing for custom fills and adjustments as needed. The choice between automatic and manual machines often comes down to balancing budget, production volume, and the need for precision.

The Best Automatic Fillings Machines

4 Essential Advantages of Automatic Vape Cartridge Filling Machines

Automatic vape cartridge filling machines are built for high precision and flexibility across various cartridge sizes, enabling companies to maintain consistency and reduce material waste. Let’s take a closer look at the advantages of these filling machines and how they elevate production processes:

1. Consistent Product Quality

High-quality filling machines offer precise filling accuracy, ideal for businesses looking to ensure each cartridge is filled to exact specifications. These machines are calibrated to achieve highly accurate fills, which is essential for maintaining consistency and meeting regulatory standards. By filling each cartridge with a consistent volume, they help to reduce waste and enhance product quality, ensuring a uniform experience for end users.

2. Advanced Temperature Control

Temperature stability is key when working with oils and botanical extracts, as fluctuations can lead to degradation. CleanCore’s filling machines incorporate reliable heating features to ensure optimal temperatures, supporting consistent filling quality. These heating capabilities help maintain the desired viscosity for smooth filling and prevent issues that arise from uneven heating.

3. Optimized Production Capacity

Top-tier filling machines are designed to handle medium to high production volumes, making them ideal for businesses seeking efficient production. Models like the Small and Large Filling Machines allow for a streamlined filing process, increasing production output without sacrificing accuracy. This capability enables manufacturers to fill multiple cartridges quickly, meeting demand in high-volume environments.

4. Cost Efficiency

With automation, filling machines reduce the need for manual labor, which lowers labor costs and minimizes human error. For businesses seeking to optimize their return on investment, these machines provide a quick and accurate filling solution that requires minimal labor input for setup and operation. By reducing waste and maximizing accuracy, automatic vape cartridge filling machines help businesses save on materials and improve cost-efficiency.

Ready to Optimize Your Operations? Schedule a Demo

How to Choose the Right Automatic Vape Cartridge Filling Machine: 5 Features to Look For

1. Precision Filling Accuracy

Look for cartridge-filling machines engineered for precise filling to ensure that each cartridge receives the exact volume required for consistent product quality. This precision is essential for both low-volume product filling and high-volume production, allowing businesses to fill cartridges accurately down to the smallest bit of product. The high level of accuracy minimizes waste and maintains quality across every unit.

2. Reliable Heating Systems

Machines equipped with dependable heating elements offer optimal temperature stability during the cartridge filling process. Heating systems help maintain the correct temperature for oils and botanical products, ensuring smooth filling without overheating or damaging the product. This feature guarantees the integrity of each batch of material by delivering consistent quality and a uniform appearance in vaporizer cartridges.

3. Streamlined Production Capacity

Look for machines capable of filling entire trays of cartridges at once, boosting production efficiency and saving time. Models such as the Large Filling Machine can handle larger production batches, allowing businesses to fill multiple cartridges in a single cycle. This high-capacity filling solution is ideal for companies looking to expand their output without increasing labor costs.

4. Warranty

A reliable warranty policy protects businesses from potential defects in materials or components. Warranties support uninterrupted productivity by covering any manufacturing issues that might arise, helping maintain smooth operations and high-quality output. For any additional support, customers can contact the customer service team filled with qualified experts who have trained on the machines to address specific setup and machine maintenance needs.

5. User-Friendly Assembly and Setup

The best vape cartridge-filling machines are designed with user-friendly assembly and intuitive operation, making it easier for businesses to get up and running quickly. An advanced design simplifies the cartridge filling setup, allowing users to focus on achieving the best results without extensive adjustments or lengthy setup times. This ease of use supports businesses in producing high-quality products efficiently and consistently.

Unlock Efficiency – Book a Demo with Us

Popular Cartridge Filling Machine Models

These models are designed to help businesses achieve consistent, high-quality results while reducing operational costs. By choosing the right filling machine based on production volume, cartridge type, and business needs, companies in the vaping industry can streamline their operations and deliver top-notch products to their customers.

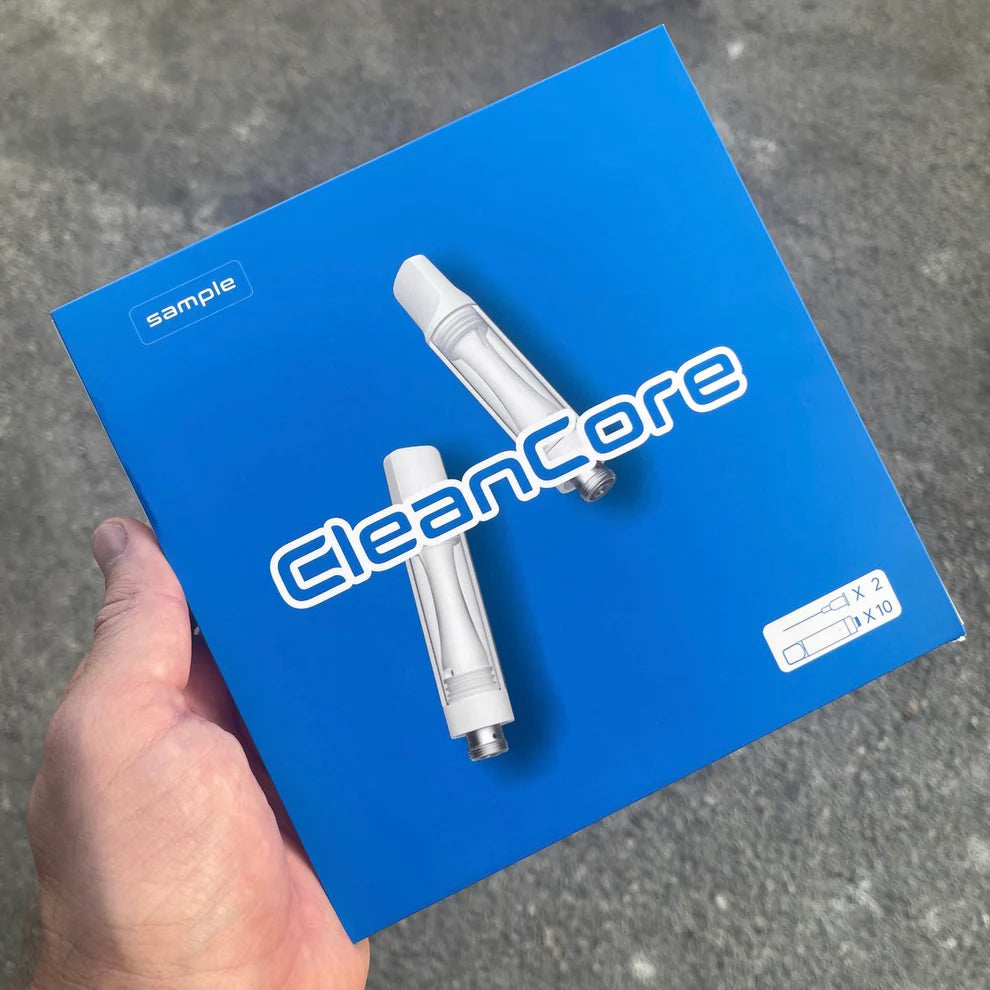

The Small Filling Machine

The Small Filling Machine is a versatile, entry-level model designed for businesses that require precision in small to medium-scale cartridge production. This machine is ideal for companies looking to start or upgrade their filling process with a cost-effective solution without sacrificing quality. Key features include:

- Precise Filling Volume Control: The Small Machine ensures each cartridge is consistently filled with the exact volume while reducing oxidization via an upside-down filling method.

- Easy Setup and Operation: Designed with user-friendliness in mind, the Small Machine requires minimal training, making it perfect for businesses new to automated filling.

- Reliable Heating System: This model includes dependable heating elements that maintain optimal temperatures for filling oil cartridges and other materials, preserving product quality.

The Small is a solid choice for small to medium-sized businesses seeking efficient and reliable filling at an affordable entry point.

The Medium Filling Machine

The Medium Filling Machine is built for increased production volume and consistent precision. Ideal for businesses scaling up and looking to maximize output with minimal labor input, the Master combines reliability with ease of use. Notable features include:

- Increased Capacity and Versatility: The Medium Filling Machine handles a range of cartridge sizes and materials, allowing businesses flexibility in meeting diverse market demands.

- Heating Capabilities for Stable Filling Conditions: The Medium Filling Machine includes heating features to maintain optimal temperature during the filling process, helping prevent fluctuations that could impact product quality.

- Durable Construction for High-Volume Use: Designed with durability in mind, the Medium Filling Machine is suitable for high-volume operations, providing a long-lasting, low-maintenance solution for growing businesses.

- User-Friendly Interface and Setup: With an intuitive design, the Medium Filling Machine simplifies the cartridge filling setup, making it easy to train operators and transition quickly into production.

The Medium Filling Machine is a great option for businesses seeking more flexibility, durability, and capacity without added complexity in their operations.

The Large Filling Machine

For businesses needing greater output and efficiency, the Large Filling Machine is an ideal choice. This high-capacity model is designed for large production volumes, meeting the demands of companies aiming to maximize throughput. Key features include:

- Efficient High-Volume Filling Capability: The Quantum is designed to handle high-demand production efficiently, helping to reduce labor costs and speed up the cartridge filling process.

- Reliable Heating Features: Equipped with heating capabilities, the Quantum maintains stable filling temperatures to support consistent product quality across all cartridges.

- Durable Construction for Long-Term Use: Built for resilience, the Quantum is designed to support high-volume operations and long-term use in demanding production environments.

The Large Filling Machine is best suited for larger businesses or high-volume manufacturers seeking an efficient, dependable machine to handle high-capacity cartridge filling with minimal downtime.

CleanCore: Buy an Advanced Vape Cartridge Filling Machines

CleanCore specializes in innovative, high-quality filling machines designed to meet the needs of businesses in the vaping and cartridge production industries. Each machine is engineered to support a range of production volumes, making it easy for businesses to scale up as needed.

Whether you're a small operation or a large-scale manufacturer, CleanCore’s solutions are designed to elevate your production quality, streamline operations, and support your growth. Shop now and discover how CleanCore’s expertise can help you achieve consistency, reduce waste, and meet industry demands with confidence!