For businesses in the vaping industry, maintaining quality and efficiency is key. A vape cartridge filling machine is an advanced solution for filling cartridges accurately, minimizing waste, and ensuring each cartridge is filled with precise consistency. These machines provide reliability, speed, and flexibility that manual filling methods can't match.

In this guide, we explain the top advantages, essential features, and practical considerations to help you choose the perfect cartridge-filling solution for your needs. Ready to streamline your cartridge production and elevate the quality of every unit? Let's explore the ins and outs of vape cartridge-filling machines!

What Does a Vape Cartridge Filling Machine Do?

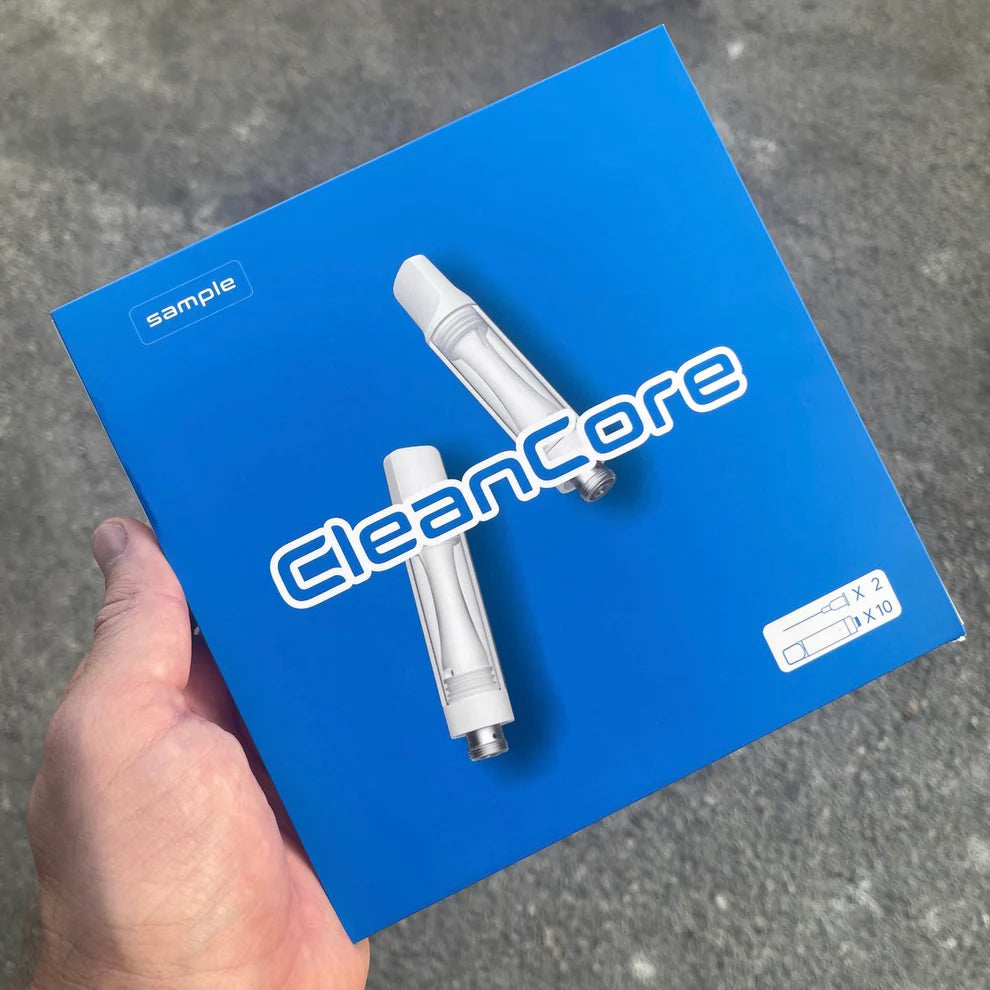

A vape cartridge filling machine is a specialized device used to fill vape cartridges with oils, distillates, or other vaping liquids in a precise and efficient manner. This machine automates the filling process, ensuring that each cartridge receives a consistent and accurate amount of product, which is crucial for quality control.

Designed to handle various cartridge sizes and compatible with different types of oils, these machines are essential for manufacturers in the vape industry aiming to scale production and maintain product consistency. By reducing manual labor, minimizing spills, and preventing overfills, vape cartridge filling machines streamline production, improve efficiency, and help companies meet industry standards.

Discover the Benefits Firsthand – Request a Demo Today!

The 4 Key Benefits of Using a Vape Cartridge Filling Machine

1. Unmatched Accuracy and Precision

Advanced filling machines are engineered to provide exceptional filling accuracy for a wide range of cartridge sizes, ensuring that each unit meets the precise volume required. For businesses filling 1 ml or 2-gram cartridges, CleanCore machines are designed to reduce variations, supporting accurate, repeatable fills that are essential for quality control. For instance, the Small Filling Machine can efficiently handle high volumes, filling up to 300 units per hour without compromising on precision, making it a valuable asset for businesses with high output demands.

Filling Accuracy Features:

- Stainless steel construction offers durability and supports stable connections, reducing the chance of leaks.

- Pressure regulation within the recommended range (0.5-0.7Mpa) helps manage air and filling pressure for consistent results.

- Integrated temperature control maintains stability for filling oils and distillates, preventing temperature fluctuations that could affect fill accuracy.

2. Cost-Effective and Labor-Reducing Design

Automating the cartridge filling process with automatic filling machines allows businesses to cut down on labor costs by minimizing manual work. Using pre-capped, closed system cartridges, each machine is designed to streamline the filling process, making it easier for businesses to focus labor resources on higher-value tasks rather than repetitive filling operations. For example, the Large Filling Machine is built for heavy-duty operations, providing efficient output with less need for intervention, which can reduce overall labor costs.

Cost-Saving Features:

- High-durability stainless steel and robust construction reduce the need for frequent repairs or replacements.

- Efficient part replacement options and modular design allow for quick adjustments, extending the machine’s life.

- Machines operate at energy-efficient settings, minimizing operational costs over time.

3. Advanced Temperature Control

Temperature control is vital in cartridge filling for maintaining the quality and consistency of oils, distillates, or other heat-sensitive materials. CleanCore filling machines are designed to provide stable temperature management, which is critical for businesses working with botanical or oil-based products. These machines help ensure that each cartridge is filled at the correct temperature, reducing the risk of clogs or inconsistencies.

Heating Technology Features:

- Stainless steel filling tubes maintain stability at high temperatures, ensuring smooth product flow without compromising quality.

- Consistent temperature control minimizes the likelihood of temperature-related errors, optimizing the filling process for a variety of products.

4. Compatibility with Diverse Cartridge Types and Sizes

CleanCore’s cartridge-filling machines support a broad range of cartridge types, making them versatile for the vaping industry. With compatibility for 1ml cartridges, 2ml cartridges, and other standard sizes, CleanCore machines can accommodate multiple cartridge types, ensuring that businesses can scale production without worrying about machine adaptability.

Compatibility Features:

- Stainless steel barrels and components provide high durability, reducing wear when working with large quantities of oils or botanical products.

- Machines can handle high-volume requirements for businesses that need flexibility in production scale.

With robust temperature control, cost-saving design, and compatibility with various cartridge materials and sizes, CleanCore provides a perfect solution for businesses looking to improve filling accuracy and streamline cartridge production efficiently.

Ready to Optimize Your Operations? Schedule a Demo

Top 5 Features to Look for in a Vape Cartridge Filling Machine

1. Precision Filling and Accurate Measurement

Accuracy is crucial, particularly in low-volume product filling where even a bit of product variation can impact quality and customer satisfaction. Machines must support repeatable and reliable fills for businesses that require high standards in their cartridge filling setup. One of the standout benefits of CleanCore's machines is their ability to fill cartridges with precise accuracy, ensuring consistent volumes across a variety of cartridge types.

2. Durable and High-Quality Construction

Stainless steel tubes and other robust parts are designed to withstand frequent use with minimal wear, which is essential for handling larger batches of material or dozens of carts without frequent maintenance. CleanCore’s filling machines are constructed with stainless steel and high-durability materials, ensuring long-lasting performance. This high-quality construction supports long-term use and reduces the cost of labor associated with repairs or downtime.

3. Efficient Temperature Control and Heating

Consistent temperature is critical when filling heat-sensitive oils and distillates. CleanCore machines are equipped with heating elements and temperature-stabilizing features that maintain consistent heat during operations. This prevents temperature fluctuations, ensuring that each cartridge is filled smoothly.

4. Streamlined Cartridge Filling Process and Support

High-performance filling machines streamline the cartridge-filling process, allowing businesses to manage large volumes effortlessly. Capable of filling entire trays or multiple cartridges in one go, these machines are built to optimize production and enhance operational efficiency. This level of automation not only reduces labor costs but also ensures consistent quality across every batch, making it an ideal solution for businesses aiming to scale efficiently.

5. Easy Maintenance and Cleaning

To maintain high standards of hygiene and reduce the risk of contamination, filling machines must be designed for efficient cleaning. With CleanCore machines, the cleaning process is streamlined, allowing operators to clean machines quickly and effectively. This ensures each batch maintains quality standards.

Unlock Efficiency – Book a Demo with Us

Practical Tips for Businesses Considering a Vape Cartridge Filling Machine

- Evaluate Cartridge Sizes and Types: Make sure the machine you choose is compatible with the cartridge sizes and materials specific to your product line, such as 1 ml and 2 ml cartridges commonly used for oils and botanical products.

- Temperature and Pressure Monitoring: Select a machine with consistent temperature control and stable pressure settings, like upside-down filling, to prevent issues like clogs and ensure a uniform filling process, particularly for heat-sensitive products.

- Warranty and Support: Opt for models that include a warranty with options for ongoing technical support. CleanCore machines come with customer support options that ensure businesses have access to maintenance assistance if needed.

- Consider the Filling Volume: Machines with adjustable filling volume settings help maintain control over product output, particularly for businesses with varied production needs.

See How It Works – Request Your Demo Now!

CleanCore: Advanced Filling and Cleaning Solutions

CleanCore is a leader in eco-friendly and efficient cleaning technology, specializing in advanced filling and cleaning solutions designed for businesses across various industries. Our high-performance filling machines combine precision, durability, and ease of use, catering to the unique needs of our clients from around the globe. With a commitment to customer satisfaction and cutting-edge technology, CleanCore provides essential tools for companies aiming to enhance both efficiency and environmental responsibility.